Tungsten Carbide Punch Stamping Features

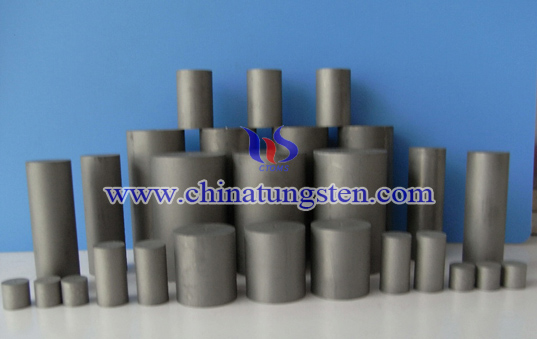

Tungsten carbide punch is an advanced manufacturing technology and far-reaching important equipment. Tungsten carbide punch has high efficiency, high material utilization, excellent part quality, good process adaptability, etc., are widely used in automobiles, machinery, aerospace, aviation, light industry, electronics, electrical, instrumentation and other industries.

Carbide materials with high hardness, wear resistance, high compressive strength, brittleness, etc., generally used in the manufacture of high precision punch complex structure. Due to processing difficulties, long production cycle, the punch is costly and requires special assembly techniques, etc., and therefore decide whether to adopt should be preceded by a comprehensive study of tungsten carbide punch stampings economic performance under a variety of factors. Currently carbide is mainly used for multi-position progressive punch stamping and with mainly small and medium stamping punch manufacturing.

Tungsten carbide punch stamping technology has several features:

1. high productivity and easy to operate. Per minute, tungsten carbide punch high-speed presses to produce hundreds of thousands of pieces;

2. general without cutting, saving raw materials, energy saving;

3. dimensions by punch stamping to ensure a stable product size, interchangeability number. "Identical";

4. stamping products thin wall, light weight, stiffness, and can be complex machining shapes small clocks, large car all the beams, covering parts. Meanwhile, tungsten carbide punch stamping page there are some limitations, mainly due to the punch manufacturing is the single and small batch production, high precision, is a technology-intensive products, high manufacturing costs. Therefore, only adapt to mass production.