Tungsten Carbide Punch Performance Improvement

Tungsten carbide punch has high hardness, hiigh strength, corrosion resistance, abrasion resistance, and its coefficient of expansion are better than any other kind of tool steel, but it also has poor flexural strength and toughness. Therefore, to improve the performance of tungsten carbide punch should improve its flexural strength and toughness aspects.

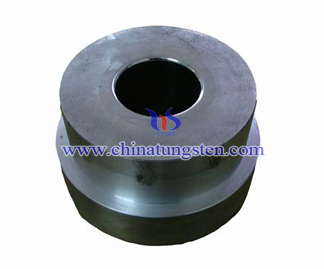

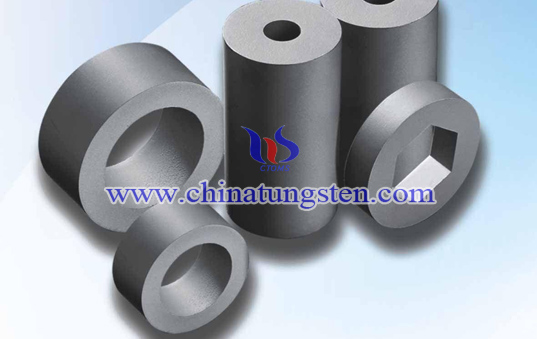

Tungsten carbide punch is made of tungsten carbide cobalt alloy, on the impact of small and high wear resistance of the punch, including

the choice of a lower amount of cobalt carbide. On the impact of large molds can be used contain higher amounts of cobalt carbide. Steel bonded carbide is a new type of punch material, which is based on one or more of carbides (such as TiC, WC, etc.) for the hardening phase, alloy steel (high speed steel, chrome molybdenum steel, etc.) powder for bonded agents, the use of powder metallurgy process, after the ingredients, mixing, pressing and sintering machinable high wear resistance. Steel bonded carbide substrate is steel, carbide overcome poor toughness, processing difficulties shortcomings, can be cut, welding, forging and heat treatment. Contains a lot of steel bonded tungsten carbide, steel bonded tungsten carbide punch components can be designed, the matrix component has extensive adjustability die failure mode according to its strength, toughness index between steel and hard between alloys. Although lower than the carbide hardness and wear resistance, but still higher than other steels, quenched hardness of up to 68 ~ 73HRC after tempering.Because sliding fit tungsten carbide punch member during operation and the hammer has long been frequently affect the quality of the mold wear, tungsten carbide powder raw material has high hardness, strength, wear resistance and corrosion resistance, is to improve the quality of mold a very

important factor. Tungsten carbide punch design should ensure that the mold parts have sufficient strength and stiffness, while the choice of material hardness of tungsten carbide powder and high quality of products to meet customer requirements. Angle to the respective surface parts of the cemented carbide materials are designed to be made of rounded filtered, stress concentration can be avoided, and for parts made of: punch, the cavity and the punch part, in the core structure having a protective effect. Greatly improve the manufacturing yield of the technical content and quality stability.