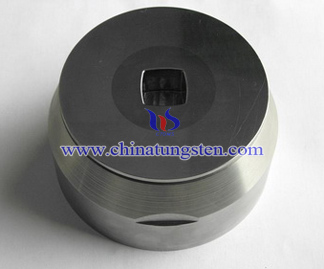

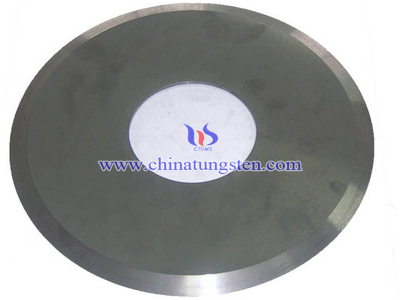

TTungsten Carbide Punch Specifications

Details of tungsten carbide punch and dies:

1.size of rough products has good consistency, it is good for technical controlling subsequently.

2.the products have good density.it is optimized of best balance between of wear-resistance and flaking concussion resistant.

3.have good characters

4.the size of pressing die can meet the requirement of the technical analysis

5.some of products have die for pressing already.

Tungsten carbide specifications that we recommend as below:

| Grade | Density g/cm3 | TRS N/mm2 | Hardness(HRA) |

| YF 10.1 | 14.80-15.15 | ≥1880 | ≥91.0 |

| YF 10.2 | 14.30-14.65 | ≥2430 | ≥91.8 |

| YL 80 | 13.75-14.05 | ≥3200 | ≥89.5 |

| YL 80.1 | 14.7-14.90 | ≥2020 | ≥89.5 |

| YG 6A | 14.80-15.10 | ≥1580 | ≥91.5 |

| YG 6X | 14.70-15.10 | ≥1600 | ≥91.0 |

| YG 8 | 14.60-14.8 | ≥1840 | ≥89 |

| YG 15 | 13.90-14.20 | ≥2700 | ≥86.5 |

| YG 20 | 13.40-13.7 | ≥2480 | ≥84.5 |

The details of tungsten carbide punch:

1)Surface finish better than 0.005 mm.

2)Roundness tolerance down to 0.002 or lower.

3)Diameter and length tolerances from a few mm.

4)Advanced highly technologic machines to assure the quality.

5)Punch pin applied in the punching mold and sophisticated wear-resistance parts in the use of molding of precision parts.

6)Tungsten carbidel for exceptional interval between regrinds. near polished flanks to reduce friction and eliminate galling. Exceptional dimensional accuracy for improved hole quality.