Tungsten Carbide Punch Design

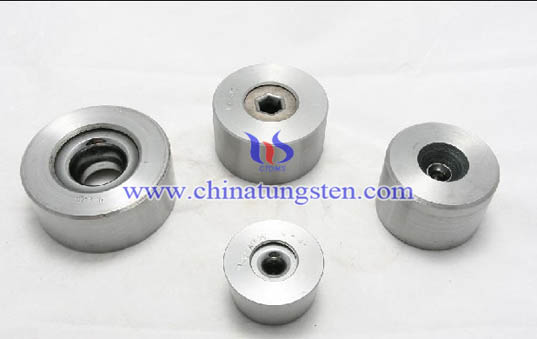

Reasonable structure can improve the life of tungsten carbide punch. For example, punching mold, guide mechanism to improve the convex and concave mold relative stability during the stamping process, thus ensuring punch within a reasonable range of punching blanking clearance. The rationality and stability blanking clearance tungsten carbide punch life is the increase of important measures. Accurate guide to reduce the relative motion relations wear parts, to avoid the convex and concave mold gap unreasonable due to a "bite wounds" and other failure modes. Especially in fine blanking punch, precision guide mechanism is an important safeguard to ensure tungsten carbide punch design success. Therefore, in order to improve the life of tungsten carbide punch, we must correctly select and guide precision-oriented form. Precision guided the choice should be higher than with the precision of convex and concave mold.

For multi-punch punching, the punch diameter in several different, the lower distance and close the case, if the small punch small and longer, can easily cause instability or broken. For hole punching, you must increase the punch guide to improve the strength of the punch, which is a prerequisite to ensure tungsten carbide punch to work properly. Accurate calculation process can also increase the life of the mold. Such as computing power and discharge stroke. If the calculation are not allowed, is likely to cause fatigue spring break or failure. Calculate the height of the mold and press Select, reasonable positioning and guiding mechanism, etc., can effectively improve the life of tungsten carbide punch. For the calculation of the size of the design and take the side of the continuous mode nesting is also crucial.

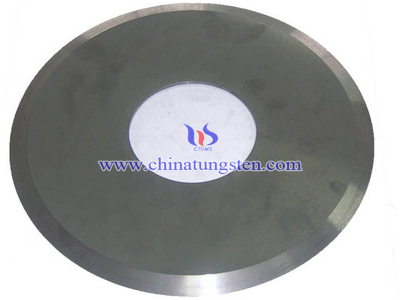

Tungsten carbide punch stamping gap refers convex, poor lateral dimensions of the die edge. A great impact on the life of the punch gap is stamping process and punch design an extremely important issue. Convex and concave punch gap size directly affects the quality and life of the punch, the gap is too large or too small will cause the edge passivation or wear.